how does vapor honing work

Vapor Honing is a surface refinishing process used to clean and resurface ferrous and non-ferrous metals. Vapor Honing often known as wet blasting is a technique used to polish precise surfaces.

Vapor Honing Bonehead Performance

Blast Wash Systems has partnered with Vapor Honing Technologies Force Automation to deliver the next great thing in advanced robotic wet blasting.

. Vapor honing can be used on almost any surface found on a motorcycle or car including gloss plastic. Vapor Honing is the same process as wet blasting and vapour blasting. Are favorite application is carbs for the finish it provides.

It cleans in areas other methods cant. You will most commonly find vapor chamber cooling in high-performance laptops and. Instead of dry abrasive media used in sandblasting it uses a combination of water compressed air detergents with finer and gentler media to remove oxidized metal and corrosion.

You also might be asking yourself questions such as. It is commonly used for cleaning aerospace parts and surfaces. Youll notice a difference within about ten minutes.

How Does Vapor Honing Work. No matter the size or weight of a part we can customize a system to meet your needs whether it be a single or multi part process. On aluminum it leaves a finish that looks almost like paint.

This was created as an alternative in the 70s to the use of crystalline silica in sandblasting processes which was causing irreversible lung diseases. The process has numerous functions for example-. Give it up to two hours for edibles and a bit less.

Vapor honing also known as vapor blasting wet blasting or wet honing is a process that mixes an abrasive media with water to create an unparalleled finish and is much gentler on parts than acid baths or sandblasting. Vapor honing also referred to as vapor blasting or wet blasting is a surface refinishing process used to clean and restore surfaces. The abrasive nature of the cleaning means the part is scrubbed clean by default.

It is the ideal for all types of materials metallic and non-metallic. Water abrasive and compressed air are 3 ke. Its perfect for restoration work because it makes the metal surface look like new but does not remove metal like sandblasting.

What is vapor honing. Vapor honing is a finishing process that utilizes water and various types of fine media to restore parts to OEM finish. While it can handle a wide variety of materials it gives a excellent finish aluminum zinc brass and magnesium.

Cooling Modern Electronics. Vapor honing is a low pressure wet blastin g process that safely cleans restores parts leaving a nice finished surface. Using a combination of compressed air and a flow of water borne abrasives this process gives a smooth and fine finish unlike dry blasting it leaves no damage to your parts.

It leaves a smooth satin finish and is much more gentle to the surface than dry sand or glass bead blasting. WHAT IS VAPOR HONING. 2 days agoSmoking CBD flower or CBD vapor is the quickest way to feel the effects.

Vapor honing has many advantages such as being dust free preserving the surface finish of the part and creating a brilliant finish. Vapor Honing uses a slurry of water compressed air detergents and abrasive media. Vapor blasting also known as wet blasting liquid honing or dustless blasting is a process that uses pressurized water and abrasive material to remove contaminants corrosion residue or coatings from a surface.

Perfect for use on new components or refurbishment of any type of machinery. Before you start the cleaning process you need to pick the type of abrasive youll use to clean your part. Since then vapor honing has become popular in many industries from construction to.

Vapor chambers are sometimes integrated with heatsinks to aid in the cooling process. Wet Blasting Equipment Vapor Blasting Services. Vapor Honing Did you know that vapor honing is one of the most advanced technologies you can use for finishing and cleaning surfaces.

This process also seals the pores of the aluminum making it look better longer and be more resistant to future corrosion. If youre sensitive to smoke you can try tinctures or edibles. The vapor blasting process provides the highest quality soft surface finish.

Vapor honing is one of the most modern technologies out there for finishing and cleaning surfaces. Vapor honing is also a great choice for removing very tiny scuffs and tool marks as well as for applications that need a satin-smooth. With water serving as lubricant the pressurized slurry mixture wont scar heat or warp the original surface of the part allowing even delicate internal engine components to be vapor honed.

Whatever industry youre inwhether youre an engineer a mechanic or a hobbyistvapor honing is a great technology for you to use. No media is impregnated into the component nor is there any dust created by the break-up of media unlike dry blasting where the finish is produced by sheer force of media impact. Vapor Honing Technologies Lilhonda Com Vapor Hone 1000 Wet Blasting Equipment Wet Cabinet Made In The Usa Vapor Honing Jim S Workshop Vapor Blasting.

Vapor chamber cooling is a type of heat-spreader technology that uses evaporation and condensation of liquid to cool down an electronic component. To remove imperfections such as heat treat scaling you add fine abrasives to the water then sprayed onto the material at great speed. The key to vapor blasting is that the finish is produced through the flow of water borne abrasive giving a finer finish due to the flushing action of the water.

How does vapor honing work Tuesday March 1 2022 Edit. Using a fine glass bead slurry mix with 25-60 psi 37 cfm this is a high volume low pressure process that gets down into the fine areas removing any dirt grime rust or corrosion without removing any metal. These will take a bit longer to kick in because it takes time for your body to digest and process.

Vapor honing is a wet blasting process which uses very fine glass beads and water under air pressure.

A Simple Introduction To Vapor Honing Issuu

Slurry Blasting Vapor Blasting Equipment For Sale Vapor Honing Technologies

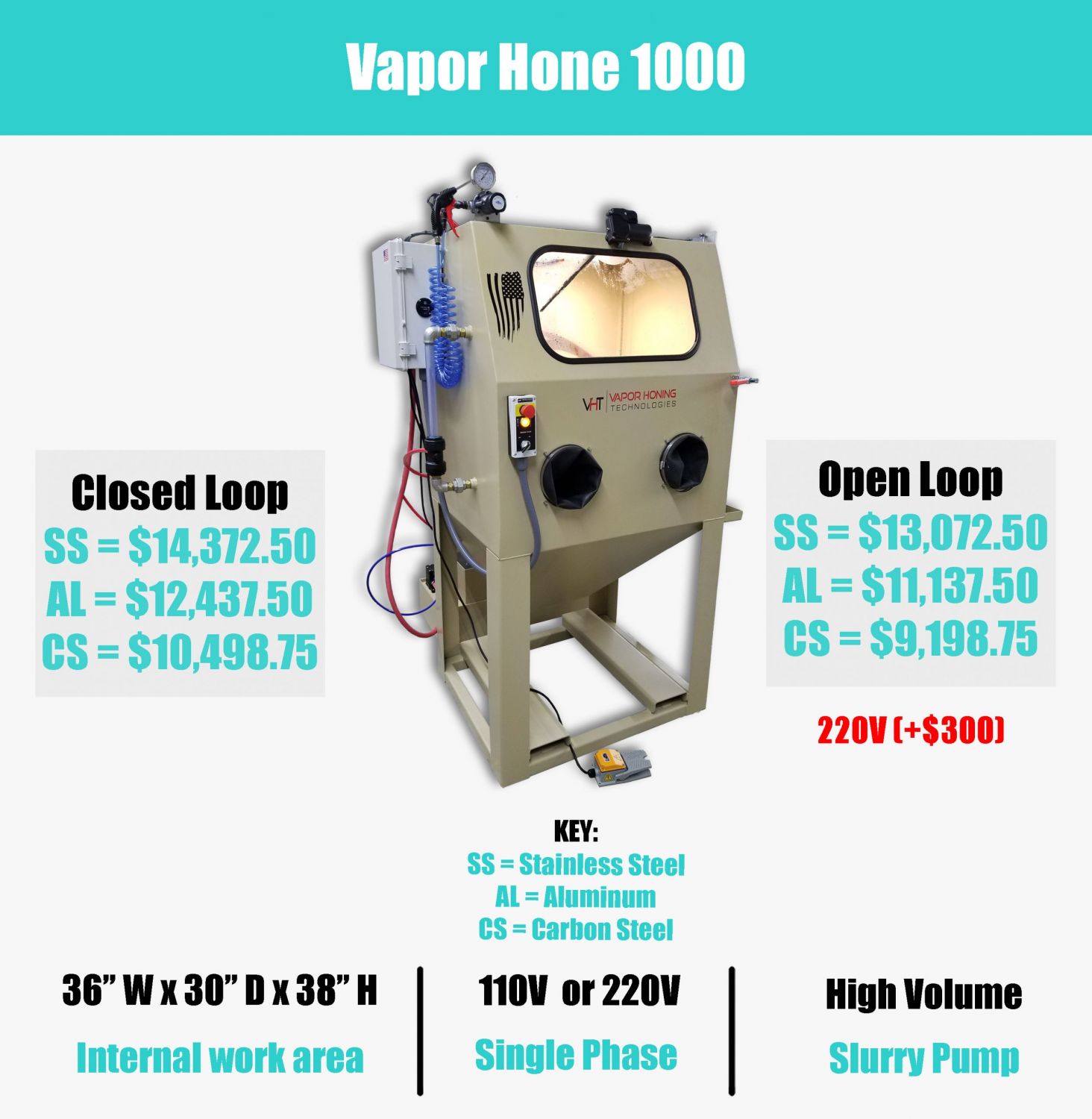

Vapor Hone 1200 For Sale Vapor Honing Technologies

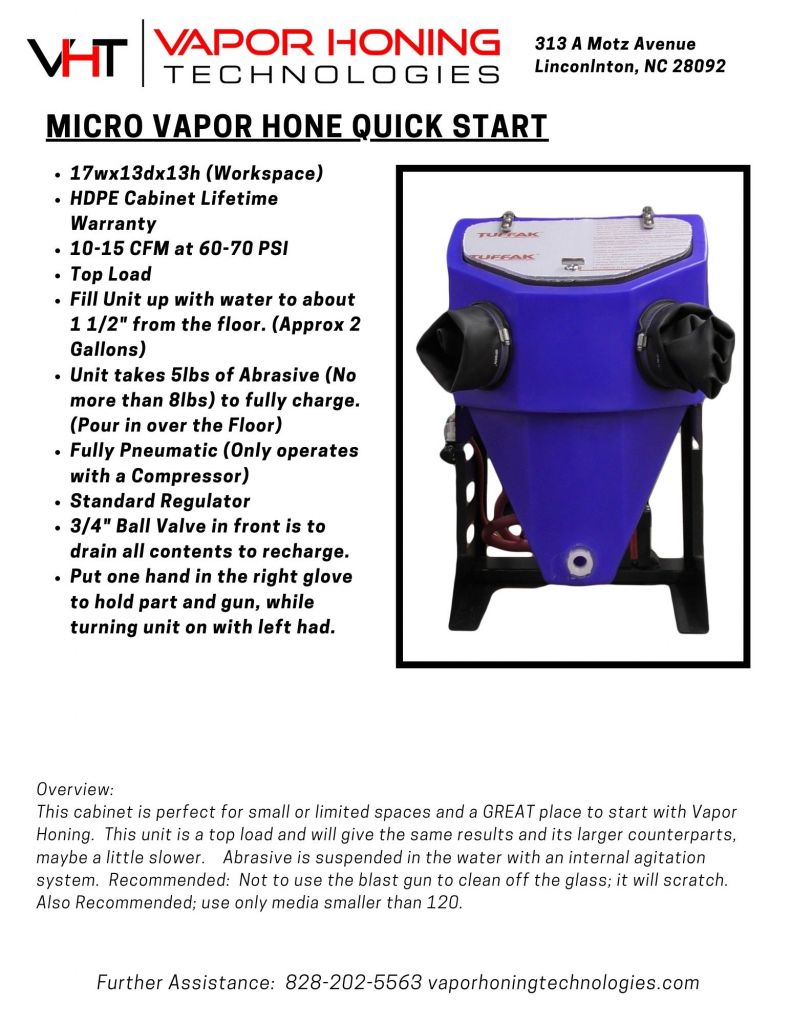

Quick Start Vapor Blasting Equipment For Sale Vapor Honing Technologies

Vapor Honing Sales And Services Laserclean

Before After Vapour Blasting Automotive Restoration Repair Vapor

Vapor Hone 1000 Wet Blasting Equipment Wet Cabinet Made In The Usa

How To Vapor Hone A Carburetor Vapor Honing Technologies Youtube

Vapor Honing Setup Harbor Freight 40 Lb Sand Blast Cabinet Mods With Complete Parts List Youtube Auto Body Work Homemade Tools Harbor Freight Sandblaster

Why You Should Buy A Vapor Honing Machine Vapor Honing Technologies Youtube

Difference Between Dry Wet Blasting Vapor Honing Technologies Youtube

Vapor Hone Up And Running Bike Builds Motocross Forums Message Boards Vital Mx

Slurry Pumping System S Vapor Honing Technologies Youtube

Vapor Honing Blasting Superfly Garage

Vapour Blasting Machine And Capabilities Vapor Honing Technologies Youtube

Vapor Honing Glass Bead Blasting Media Visual Finishes By Grit Youtube Glass Beads Glass Vapor

What Is Vapor Honing Vapor Honing Technologies Youtube